Services

Services

Services

- CNC Machining

- CNC Machining

We are focusing on:

- Industries

- Resources

- About Us

- Contact

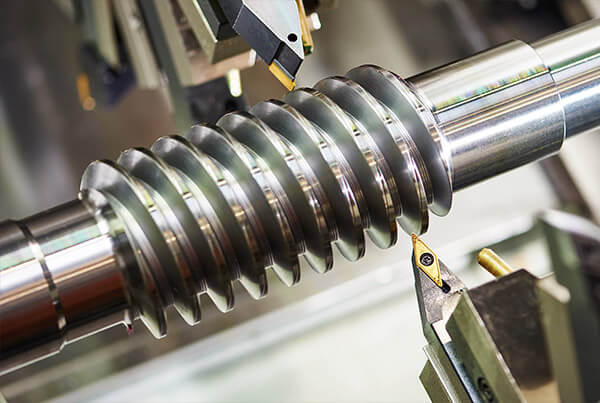

Of 3ERP’s various CNC services, CNC turning is frequently requested for a certain category of parts. Turning is a CNC machining process in which the workpiece is rotated at speed in a chuck. Unlike with CNC milling, the cutting tool does not spin.

Turning can be carried out on metals like aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium and nickel alloy, as well as plastics like nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, PEEK. CNC turning machines are also known as lathe machines.

CNC turning machines are ideal for creating round or cylindrical parts. Lathes create these parts quickly, accurately and with excellent repeatability.

Although generally used for parts of a certain shape, CNC turning can still be used to carry out a variety of cuts, including drilling, boring, threading and knurling.

To discover the more general advantages of CNC machining with 3ERP, see our CNC machining services page.

CNC turning is a particular form of precision machining in which a cutter removes material bymaking contact with the spinning workpiece. The movement of the machinery is controlled bycomputer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multipleangles at the workpiece, which is usually stationary. Because CNC turning involves rotating theworkpiece in a chuck, it is generally used to create round or tubular shapes, achieving far moreaccurate rounded surfaces than would be possible with CNC milling or other processes.

The tooling that is used with a CNC lathe machine is mounted to a turret, This component isprogrammed to make certain movements and remove material from raw materials until thedesired 3D model is formed.

Like CNC milling, CNC turning can be used for the rapid manufacture of either prototypes or end.use parts.

Aluminum machining is a key part of 3ERP’s services catalog, but CNC turning can also be used to process metals like magnesium, steel, stainless steel, brass, copper, bronze, titanium and nickel alloy.

CNC turning is commonly used for mechanical and aspect components, which are often made from aluminum, the most machinable metal. Aluminum parts can be made with high strength and accuracy, as well as a superior surface finish.

Aluminum machining is a key part of 3ERP’s services catalog, but CNC turning can also be used to process metals like magnesium, steel, stainless steel, brass, copper, bronze, titanium and nickel alloy.

CNC turning is commonly used for mechanical and aspect components, which are often made from aluminum, the most machinable metal. Aluminum parts can be made with high strength and accuracy, as well as a superior surface finish.

This is a lens we did for a famous automotive lighting company. Before they reached out to 3ERP, they did testing with numbers of other prototype companies. The parts they received looked brilliant at first glance, but as soon as they go for light simulation testing, none of them were able to hit the mark.

The reason? Well, simply because the prototypes from these other services were not accurate enough. So, they thought they would have to outsource from Europe. However, when they approached the 3ERP team, the company soon discovered that they had finally found a service provider that could meet their needs.

Please attach your 3D drawing (preferably STEP and IGS format). Got multiple files? Put all your files in a folder and compress the folder into ZIP or RAR file. (File Type: doc|excel|png|jpeg|csv|pdf)

Alternatively, send through your RFQ by email. projects@3erp.com